The engine piston is one of the essential working elements of the combustion engine. Inside such an engine there are at least two cylinders, in each of which a piston moves up and down. The distance traveled by the component is the stroke, hence it is also sometimes referred to as a reciprocating piston. Consequently, such engines are also called reciprocating engines.

Contents

What is the purpose of the piston in the engine?

The movement of the piston from its top dead center to its bottom dead center is linked and synchronized with other elements of the engine. The opening and closing of the exhaust and intake valves is precisely coordinated with his movements. When the piston is at its lowest point, the intake valve opens and, in the case of a petrol engine, the air/fuel mixture is sucked in. The piston then moves up and compresses the mixture. When this is caused to explode by the spark from the spark plug, the pressure pushes the piston back down, the exhaust valve opens and the exhaust gases are expelled to the outside.

The piston is also connected to the crankshaft via the connecting rod: it converts the energy generated by the combustion during the explosion into mechanical work. The movements of the piston from top to bottom are converted into a rotary movement of the crankshaft, which then transmits this to the car's gearbox.

But the component also has some other functions:

- The combustion chamber is sealed. The heat generated by the explosion is dissipated.

- i It ensures a clean gas exchange by sucking in the fresh mixture or fuel and expelling the resulting exhaust gases.

- It supports the mixture formation of air and fuel because the piston surface – the so-called “piston crown” or “fire land” – which forms the bottom of the combustion chamber is specially shaped.

- The piston rings, which act as seals, are attached to it.

Construction of the piston

The flask is hollow and open on one side and has a cylindrical shape.

It has the following areas:

- Piston head with grooves and piston rings

- Piston bosses

- Shaft

They interact with each other and with other elements in the following way: The pressure resulting from the combustion of the mixture is transmitted through the piston crown to the crankshaft via the piston bosses, the piston pin and the connecting rod.

Thesepistons

Compared to the pistons of a gasoline engine, a diesel piston is exposed to higher mechanical and heat loads. It therefore requires reinforcement in the form of a cast-in ring carrier in the first piston ring groove made of Ni-Resist, also known as austenitic cast iron, to prevent the groove from chipping and transferring material to the ring from micro-welds created by sudden heating and cooling . This material is erosion and corrosion resistant and non-magnetizable. This is ensured by the high nickel content of the material, which also guarantees very good elasticity.

What are forged pistons and what are their advantages?

Forged pistons are used when special requirements are placed on a vehicle and its engine and when they have to withstand high loads, high temperatures and increased pressure on the cylinder got to. This applies, for example, to motor sports or tuned cars as standard, but meanwhile it is also used on engines in production vehicles that have an exceptionally high level of performance.

Due to the way it is manufactured, the material is more stable, which makes the components more resistant. In addition, with forged pistons, it is possible to make the walls thinner, which means they weigh less. These more powerful engine components can absorb more energy despite being the same size. If you want to upgrade your engine with these parts, also pay attention to the increased density of the material when buying and also inquire about the appropriate improved versions of the other elements, such as the connecting rod and piston rings, because these are also exposed to heavy loads .

Did you know? The right pistons make a contribution to protecting the environment

It's not just the choice of fuel that affects how badly your car pollutes the environment. Modern internal combustion engines are now equipped with pistons whose structure and material composition are designed to achieve low-emission and complete combustion. Furthermore, these modern designs reduce friction and engine oil consumption. The pistons therefore play an important part in protecting the environment and saving raw materials.

How can the lifespan of the pistons be extended?

The piston in the car, like the entire engine block, is actually designed to remain functional for the full service life of the vehicle. Nevertheless, irreparable damage can occur with incorrect or lack of care and maintenance, regardless of whether you use conventional parts or the more resistant forged pistons.

Here are a few tips to help you maximize engine piston life:

- The mixing ratio of the air-fuel mixture must be correct. However, if the mixture is too “rich”, then too much fuel will be burned and the film of engine oil will be washed off the cylinder walls, which will drastically increase the wear of pistons in the engine and other components – at least this is true for petrol engines. On the other hand, if the mixture is too “lean”, i.e. the proportion of air is too high, the engine can overheat or the pistons or valves can burn away.

- Check the level of the operating fluids regularly. If the engine oil is scarce, the protective lubricating film on the engine components is missing, which greatly accelerates their wear. There is also dry metal-to-metal friction on the piston rings. This is also called a “piston eater”. Friction welding occurs between the surface of the cylinder and the piston. H. they bind together tightly and the motor can no longer rotate. A repair is usually difficult and very expensive, the engine often has to be completely replaced.

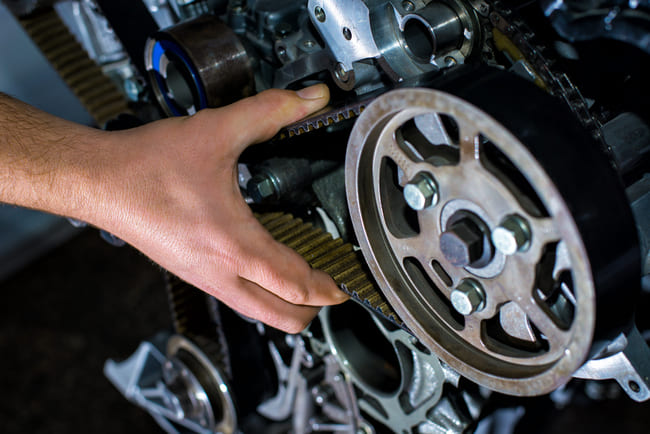

- The condition of the toothed belt must also be checked at regular intervals. This transmits the rotary motion of the crankshaft to the camshaft. Manufacturers usually specify replacement intervals for this. Ignore this and the belt will tear as a result, the camshaft will no longer be controlled properly, the valves will remain open and protrude into the cylinder and will be hit with full force by the piston, resulting in serious damage to both components.

- Change the spark plugs and always clean the air filter in good time. Due to the failure of the filter, the correct air-fuel mixture is no longer supplied to the engine; if the spark plug fails, misfires occur: if these defects occur, damage to the valves and pistons can be expected.