Engine cooling is an essential part of the internal combustion engines of modern cars to protect the engine from overheating and to ensure that it reaches its optimal operating temperature as quickly as possible. This reduces fuel consumption and minimizes pollutant emissions. Cooling also plays an important role in driving comfort, as it not only releases the excess heat from the engine to the outside air via the radiator, but also provides warmth in the vehicle interior via the heater. In this article, we will introduce you to the different types of engine cooling, describe their function and explain what can cause defects, how you can notice them and how to fix them.

Contents

What are the different types of engine cooling?

The first engine cooling systems did not have to meet the same high requirements as the cooling systems of today's engines. Therefore, air cooling was initially used to protect the engine from overheating with the help of the ambient air. In these systems, the cylinders and cylinder heads were equipped with large cooling fins in order to increase their surface area and thereby release the heat generated during combustion of the air-fuel mixture into the surrounding air. In addition, air baffles and fans were used to support air cooling.

However, this type of engine cooling can no longer meet today's requirements for efficiency, faster heating of the engine and vehicle interior, longer component life, high performance and reduced fuel consumption. This requires the engines to reach their optimal operating temperature quickly and maintain it constantly. This only became possible with the introduction of thermostat-controlled liquid cooling. Another name for this type is water-cooled, which is slightly misleading as a mixture of water, antifreeze, anticorrosive and substances that increase the boiling point is used to cool the engine.

A distinction can be made between four different types:

- Round tubes : This type is inexpensive, but allows for little heat dissipation across the surface and requires high-quality gaskets.

- Oval tubes: This type is inexpensive and requires high-quality gaskets, provides however, a larger area for heat dissipation.

- Sintering: This type is extremely powerful, has a large surface area for heat dissipation, and is highly permeable. The seals are also more resistant to damage, but this type is very expensive.

- Aluminium: This type enables first-class heat dissipation, is very robust and stable, but also the most expensive engine cooling type.

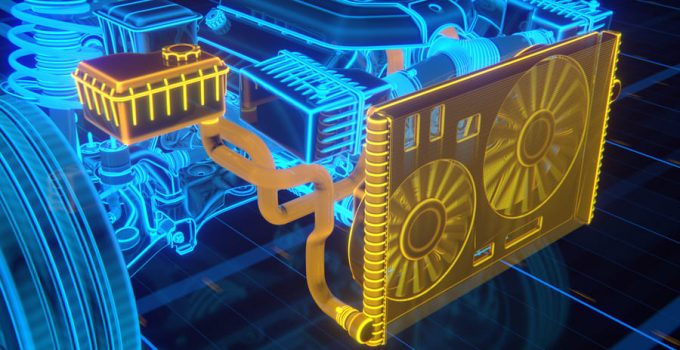

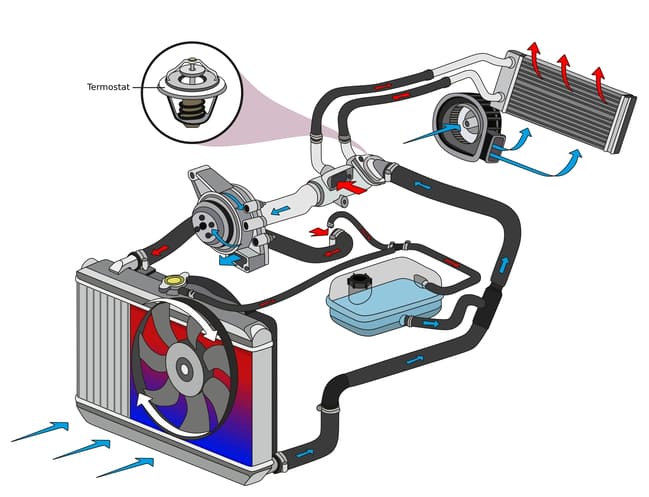

Engine cooling system structure and function

The engine cooling system in modern cars consists of several components that are connected to one another via the radiator hoses and work together to ensure that the engine is quickly heated to its optimum operating temperature (between 80 and 90 degrees Celsius), that it is protected from overheating and that the vehicle interior is kept cool the excess heat is heated. The most important components are the water pump, thermostat, radiator, expansion tank, engine fan and temperature sensors. Today, coolant is normally used for automotive engine cooling, which is sucked in by the water pump and circulates through the engine compartment, absorbing the excess heat from the engine and dissipating it to the other components of the engine, the vehicle interior or the ambient air. The water pump is driven either mechanically by a toothed or V-ribbed belt or electrically by an electric motor. Initially, the coolant only circulates in the small cooling circuit in order to bring the engine up to operating temperature as quickly as possible. As soon as this is reached, the thermostat opens the large cooling circuit to cool the coolant and keep the engine at its operating temperature. To this end, the cooling water is now transported via radiator hoses to the radiator, where most of its heat is released into the ambient air by passing the cooling liquid through a tube surrounded by fins. The water cooler is usually mounted at the very front of the engine compartment between the headlights and is protected from stone chips by the radiator grille. The cooled coolant is then returned to the engine and the cycle begins again. In order to prevent a possible overpressure caused by the expansion of the heated coolant, the car cooling system is always equipped with an expansion tank. This reservoir stores the coolant and compensates for changes in coolant volume through a pressure relief valve in the lid. If this indirect engine cooling is not sufficient, which can happen, for example, at very high outside temperatures, when driving slowly or when the car is stationary with the engine running, one or more fans can be switched on for improved cooling of the engine, which are mounted in front of or behind the radiator can be controlled mechanically or electrically using temperature sensors. This direct engine cooling ensures more intensive cooling by generating an additional air flow.

Causes of defective engine cooling

Although the functional life of the water cooling system is quite reliable, the complex structure can easily lead to defects in one of the numerous components. The individual components of the engine cooling system can be damaged due to foreign particles in the coolant, poor-quality coolant, mechanical damage, natural wear and tear, corrosion, frozen coolant, overheating, overpressure and deposits in the cooling system. Even if the radiator grille is intended to protect the radiator from stone chips, this danger cannot be completely ruled out. Apart from that, excess pressure can lead to a so-called “bloating cooler”, which in the worst case can lead to a coolant leak. Low temperatures can also be dangerous, as they can freeze the coolant, which not only causes hoses and lines to leak, but also the radiator can burst. The cause of overheating or a rapidly increasing engine temperature, especially in stop-and-go traffic, can be a defective electric motor of the radiator fan. The thermostat, on the other hand, is particularly susceptible to blockages caused by foreign particles in the coolant. The mechanical water pump is usually very strong and durable, but can be damaged by failed bearings and leaking seals due to the resulting loss of cooling water.

Signs of a failed engine cooling

You can easily spot a defect in your car's cooling system by a variety of signs. The most noticeable signs are a rapidly increasing engine temperature up to overheating and leaking coolant. The former is often indicated by a corresponding warning lamp on the dashboard, a sharply rising needle for the cooling water or engine temperature or a constantly running engine fan. The latter is noticeable through a lot of white smoke from the engine compartment through evaporation of the leaking water on the hot engine or a mostly greenish puddle under the car after a longer period of standstill. If the 90-degree mark on your temperature display has not yet been reached even after a long drive, this usually indicates a defective thermostat. If your car is not equipped with a temperature display, you can also tell that the heating is not really warm.

Repair of a defective engine cooling

In order to extend the service life of your engine cooling system and prevent possible defects, you can take the following measures:

- use high-quality coolant and change it early

- Rinse the car radiator regularly, especially when changing the coolant

- Remove external contamination such as leaves and fluff from the radiator

- do not drive with a low coolant level

- < i class="as-icon as-icon--circle as-icon--info" style="background-color: #fffff"> immediately replace cracked, hardened or deformed hoses

- when topping up the coolant, the mixing ratio specified by the coolant manufacturer must be observed

If, despite everything, a defect occurs in a component of your car's engine cooling system, we strongly recommend that you have this checked and repaired in a specialist workshop if you do not have the necessary knowledge and experience. There, smaller leaks are often repaired with the help of special liquids. Larger leaks can usually be brazed or welded. Deposits and debris inside the cooling system can be removed by washing with chemicals in the opposite direction of the cooling water circulation. If the damage is too extensive, the only solution is to replace the defective component.

Conclusion

The engine cooling system protects the engine from overheating and ensures efficient Fuel consumption and reduced pollutant emissions, making it an indispensable part of the internal combustion engine of modern vehicles. However, it is made up of numerous individual components that are more or less susceptible to defects. However, these are usually easy to recognize by the fact that the engine overheats, does not reach operating temperature, the heater does not warm up properly or coolant leaks out. If you notice such signs on your car, you should immediately visit a specialist workshop and have the cooling system checked and, if necessary, repaired or replaced.