Wishbones are an important component of your wheel suspension. If these are also the associated wishbone bushings or the wishbone rubber bearings defective, this has a negative impact on the vehicle performance because the chassis geometry is no longer correct and stable. Of course, the function of your wishbone also suffers if the wishbone is worn out or broken. But before we get into the possible defects of a control arm and the symptoms of a control arm, you must first understand its function.

Contents

What is the function of your control arm?

You shouldn't only worry about the function of your control arm when you recognize symptoms of a control arm defect. In this way, you often have the opportunity to recognize beforehand that this component could fail in the near future. With a bit of luck, you will not only save yourself repair costs in the area of the wheel suspension, but also avoid considerable follow-up costs. For this reason, we advise you to prick up your ears when your control arm squeaks.

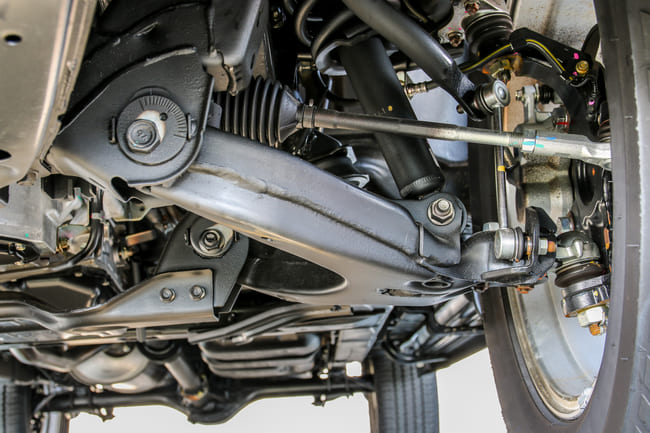

In principle, you need these components of your car to be able to control it. The individual wishbones connect the wheels of your car to the frame and thus enable the desired steering movements. In principle, these vehicle components offer a certain amount of lateral leeway, which, however, is extremely dependent on how good the wishbone bearings, consisting of a firmly pressed-in strong rubber sleeve, are still in good condition. Even a movement in height is made possible by the vehicle wishbones. If the control arm bushings are torn, the mobility suffers, so that the components either have too much or too little play. This can be symptomatically expressed, for example, by a knocking or creaking suspension.

When you drive your vehicle on the road, your wheels and the associated suspension have to adapt to very different road surfaces. A wide variety of forces are at work, to which your independent wheel suspension must react adequately. The shock absorbers and springs usually absorb the most frequent effects of force and ensure that the wheels can move up and down flexibly. If you now look at forces acting from the side, your wishbones have the task of intercepting or compensating for them. In addition, they ensure the absorption and dissipation of the pressure and traction forces that act on your wheels when braking or starting. These are supported by the corresponding tension struts.

What types of wishbones are there and where are they installed?

Over the decades, a large number of different wishbones for passenger cars have been developed. One example is the wishbone, the shape of which is usually slightly curved and vaguely reminiscent of an Australian boomerang. Alternatively, fork-shaped wishbones or double wishbones arranged in parallel can be used. The latter is a combination of two wishbones, which are independently connected to your wheel suspension at the top and bottom.

With today's standard independent wheel suspension, two wishbones are always installed (and often replaced) in pairs on your wheel suspension front axle. The same also applies to the rear axle of your vehicle. Basically, however, these vehicle parts are components that have to be precisely adapted to your chassis. This is ultimately the reason why there are so many different shapes.

What happens if your control arms are not adjusted correctly?

Depending on the setting of your wishbones, the resulting wheel position also changes. The parameters include the track (distance differences between individual wheels), the camber (wheel inclination) and the spread (wheel axis). These should always be set correctly and, under certain circumstances, adjusted after appropriate work on your chassis. Ultimately, shock absorbers, springs, tension struts and wishbones must be coordinated in such a way that a balanced wheel suspension results. If there are incorrect settings or any irregularities, for example because your control arm bushings are worn out or the guide joints are defective, your driving safety will be significantly affected. It can also cause a knocking or creaking suspension. Often the general driving noise level also increases and your vehicle only drives restlessly.

Consequences of defective control arms and their durability

In many cases, your vehicle wishbones are made of very resilient materials. As a result, they have a very long service life and you rarely have to replace aluminum components. Nevertheless, there are components of the wishbones which are exposed to a very high level of wear. These include, for example, the ball head (also known as the wishbone bushing) or all the guide and ball joints. Typical symptoms that occur in the event of a defect include a lack of driving comfort, increased steering wheel play, irregular tire wear or a higher noise level. You can often get a single wishbone for less than 100 euros, but you have to reckon with about three times the cost in order to cover the particularly complex installation in a specialist workshop.

Conclusion

The connection between wheel and vehicle is ensured by the individual wishbones on each individual wheel. If these are defective, this has a significant impact on the chassis geometry, but also on driving safety. For this reason, we advise you to always have these vehicle components renewed or have them renewed immediately. This is the only way to avoid any consequential damage to your vehicle. In this article, we have not explained the function of these components to you in detail, but have also described possible defects. So you are well prepared to place an order for their replacement or to do the whole thing yourself.

A tip from CarTipsandmore:

- If a wishbone bearing can no longer be removed normally, you can use additional tools to help. One possibility, for example, is the use of a jigsaw. You can use them to cut through the wishbone bearing up to the height of the wishbone pin. In this way, the tension can be reduced, which makes removal much easier. The best way to install a new bearing is to position it slowly and evenly with a screw clamp or a vice. If possible, avoid using brute force, for example with a hammer and socket wrench, as this reduces the service life of the components enormously.

- After you have carried out repairs or other work on your wishbones in the car, you should also track your (have) check the car. This is the only way you can readjust accordingly and ensure the correct chassis geometry. This not only affects your tyres, but also ensures that your car always offers the best possible performance.