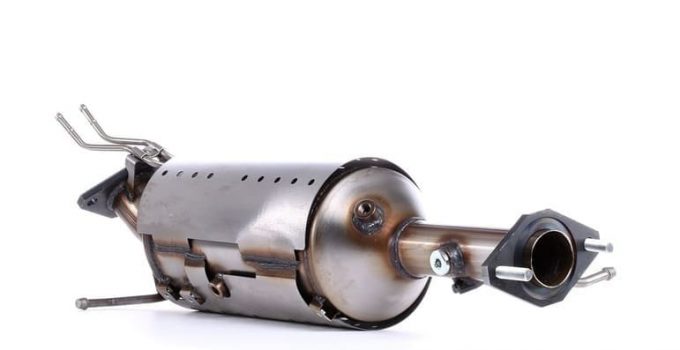

The particle filter is an important component of the exhaust gas cleaning system in diesel vehicles. The otherwise emitted fine soot particles are considered carcinogenic. Therefore, many years ago, all diesel vehicles in Europe were equipped with such filters. This contributed to the fact that air pollution, especially in the area of so-called fine dust, could be reduced considerably. The principle of these systems is that they capture soot particles, which are then completely burned off at regular intervals. The engine management usually takes care of this automatically. Nevertheless, over time, residues get stuck, so this component has to be replaced because it becomes clogged. Nowadays, however, methods have also been developed which allow the particle filter to be cleaned with an agent. We will explain the advantages and disadvantages of these processes and how to do it correctly.

Contents

How does a soot particle filter work and why is it clogged?

As already described, the main task of such components is to remove the fine dust particles from your exhaust gases as completely as possible. Certain metal constructions or ceramics are used for this purpose. The retention of the soot particles is based on the forces of adhesion. This allows around 90% of fine dust to be removed. Now you can easily imagine that your particle filter has a certain absorption maximum. But modern components of this type first clean themselves. It does this by simply completely burning the retained soot particles at regular intervals. Your engine control carries out such a regeneration cycle about every 100 kilometers. However, this requires a comparatively high exhaust gas temperature, which generally cannot be achieved on short journeys. You must therefore expect that you will experience greater wear and tear if you only drive your diesel vehicle for short distances. But even with the optimal use of the vehicle, residues remain. This is because the soot particles are not only burned to form CO2 and water, but some ash is also left behind. This wears off over time. Finally, due to the ash over time, the diesel particulate filter becomes clogged and eventually completely clogged.

How can you clean your particulate filter?

There are a few methods you can use to more effectively regenerate this exhaust aftertreatment component. These differ not only in their effectiveness, but also in the costs to be expected and the possible problems that can arise. Basically, if you think that this component is clogged, you should first rule out other causes for the observed problems. So you should first check your exhaust system and also check the correct function of the lambda probe. There is a particular need for action if the corresponding indicator lamp for the soot particle filter or the engine indicator lamp is activated.

If the latter is the case, we recommend that you first read out the error memory, as this is the only way to determine the cause. In general, we recommend that you consult your technical vehicle manual even if the particle filter light is active. Some vehicle manufacturers also use this indicator lamp to inform the driver that a regeneration cycle is urgently needed, but the required exhaust gas temperature has not yet been reached. In such a case, a corresponding procedure is usually also described for cleaning the particle filter itself. Often you only have to drive a longer distance continuously and with a higher engine load (e.g. when driving quickly on the motorway). This should be enough to „burn free“ the component again. If this no longer helps, it can be assumed that the component is completely blocked.

The most expensive, but also the safest variant of a repair is the complete replacement of this component. However, the price of spare parts alone can be in the four-digit range. It is cheaper to have the particle filter cleaned. However, this requires dismantling and sending it to a specialist company. This then uses proprietary protocols to free the component again. Above all, the deposited ash must be removed, but possibly also unburned particles must be removed. Depending on the process used, however, component damage can also occur and so far there have been hardly any studies on how this affects the catalytically active coatings. Ultimately, you don't know how long your filter will continue to work correctly afterwards. With prices in the middle three-digit range, it can still be interesting to proceed in this way.

Alternatively, Liqui Moly, for example, offers a means of cleaning the particle filter. This is a substance that is introduced into the component with a special pressure gun and DPF lance. All impurities that cause the blockage should be removed without leaving any residue. Complete removal is not necessary, but sufficient access must be provided by dismantling other components. In addition to this substance, some suppliers also offer agents that allow the particle filter to be cleaned without removing it. In most cases, these are added to the fuel. The disadvantage here is that such additives are of course also burned in the engine and more ash can remain. Ultimately, such a process is by no means suitable for prevention and you should find out more about your experience with cleaning a particle filter in advance. In particular, how long the cleaned filter was able to do its job without any problems afterwards. You don't have to spend a lot of time cleaning such a component and then after a short time the corresponding indicator light on the instrument panel lights up again.

Conclusion

There are several methods to clean a particulate filter after you have inspected all other exhaust system components, such as the exhaust manifold. This includes sprays, for example from Liqui Moly. In addition, there are other means for which it is not necessary to dismantle the component. Alternative methods of cleaning cannot be performed without removing the particulate filter and the clogged part must be sent in. In general, however, it can be said that all vehicle manufacturers advise against such an approach. In addition, there are no guarantees or minimum running times for the cleaned components. Ultimately, you have to decide for yourself whether the savings from cleaning are worth the resulting risk.

A tip from CarTipsandmore: The biggest enemy of your particle filter is short trips. We therefore strongly recommend that you regularly drive longer distances in your diesel vehicle. This makes it easier for you to reach the required exhaust gas temperature of 500 to 600 °C. This is the only way to achieve a longer service life for your particle filter, because then you will benefit from the low maintenance of this component.