In order to be able to brake well, you need the best brake pads and you need to know what the best brake discs are. The safety of the driver and passengers also depends on having an optimally functioning braking system. It is not for nothing that the principle applies: „If you brake worse, you drive faster for longer“. In the event of an accident or in dangerous situations, this can quickly make the difference between getting off lightly and serious injuries. In the following article, we will first introduce you to the basics and then go into the best brake pad manufacturers.

Contents

- 1 What do you mean by brake pads for cars?

- 2 Types of brake pads

- 3 Categories of brake pads

- 4 The main conditions of the brake pads

- 5 Recommendations for the choice of brake pads

- 6 When do your brake pads need to be replaced?

- 7 Top 8: Ridex

- 8 Top 7: Febi Bilstein

- 9 Top 6: TRW

- 10 Top 5: Textar

- 11 Top 4: Bosch

- 12 Top 3: Brembo

- 13 Top 2: Strong

- 14 Top 1: ATE

What do you mean by brake pads for cars?

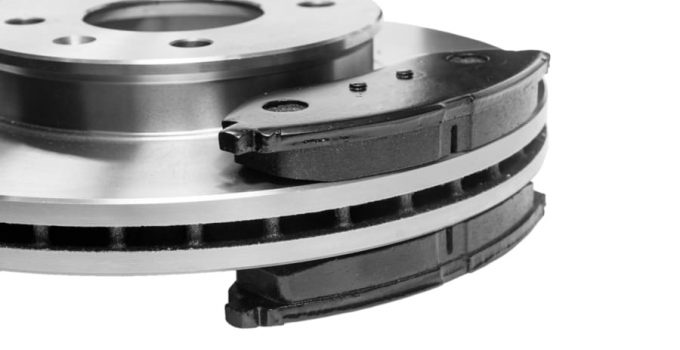

In order to recognize what makes good components of this type, you must first find out what defines the function and design of these components. Basically, the brakes on your vehicle work in such a way that the brake pads are pressed against either a brake drum or a brake disc. This happens whenever you press the brake pedal or apply your handbrake. In modern vehicles, your foot power is supported by a brake booster. Friction is caused by the pressure on the pedal and the compression of the brake components. The brake discs or brake drums are connected to the rotating wheels (they also rotate), while the brake pads are located in the brake caliper and are connected to the vehicle via them. The friction slows down the wheel rotation, which in turn allows you to slow down or bring your vehicle to a standstill. Because you use the friction to slow down, there is of course also a removal of material. The composition of the brake drum or brake disc or the brake pads is selected in such a way that a large part of the material removal affects the latter components. These are classic wearing parts that have to be replaced more or less frequently depending on the driving style and use of your car.

Types of brake pads

- Semi-metallic;

- Light metal;

- Organic ;

- Ceramic

Brake pads consist of a carrier plate and an additional pad, for Crafting can use over ten components.

The composition of semi-metallic brake pads includes at least 65% metal. The remaining 35% is a mixture of graphite and inorganic materials. The advantage of this type of pad is the ability to retain heat efficiently and the disadvantage is its excessive hardness, which leads to early wear of the brake disc.

Alloy brake pads are made from organic materials with an addition of metal (no more than 30%). They have good heat resistance and ensure more efficient braking. They cost almost twice as much as semi-metallic pads.

Kevlar, glass and carbon are the base materials to craft organic brake pads. The composition of these components does not include more than 15% metal. They are soft and very quiet and are designed to last longer than other types of pads, so they are not suitable for aggressive riders.

The composition of ceramic brake pads includes ceramic fibers, synthetic rubber and non-ferrous metals. These pads provide a constant coefficient of friction and they wear less. They are the best choice for sporty driving styles. They are more expensive than other types of brake pads.

Categories of brake pads

All rubbers are divided into two categories:

- Original

- Similar

The advantages of Original Equipment brake pads are obvious, but they cost twice as much as comparable pads. They are sold in original packaging from a trusted manufacturer.

High quality analogues differ from the original spare parts only slightly in their characteristics. These pads are cheaper while providing fairly adequate braking performance. However, there are analogues made from small materials. Usually such pads are not properly tested and do not really meet the generally accepted standards. It is important not to make a mistake when choosing these car parts: too low a price should make you think.

The main conditions of the brake pads

- Operating temperature. Brake pads resistant to a temperature of 300-350 °C should be sufficient for city driving and moderately fast driving. Sports cars are equipped with brake pads that work even at a temperature of 900 °C, but they ensure effective braking only when heated above 100 °C.

- Coefficient of friction. Pads with a friction coefficient of 0.25 – 0.35 is enough to slow the vehicle down at moderate speeds These are the values that non-original components usually have. The coefficient of friction of original brake pads is approximately 0.3 – 0.5 a maybe a bit higher. Sports brake pads at an operating temperature of 150 °C have a low coefficient of friction – 0.2. When heated, this can increase by up to 0.5.

- Durability. The wear resistance of the components depends on the material from which it is made. A soft friction lining will wear out faster, but too hard one will wear out the brake disc prematurely.

Recommendations for the choice of brake pads

- Choose pads that are similar in composition to brake discs and are manufactured by the same brand;

- When purchasing the components, be guided by the operating conditions and your own driving style;

- Only buy brake pads from trusted manufacturers.

How to distinguish an original from a fake

- Pay attention to the check mark. If you see that neither R90 nor 90R is written on the label, it's a fake.

- The package must include a product passport, warranty certificate, certificate of quality and installation instructions.

- The surface of the original brake pads should be smooth and even.

- Check the unique code number of the Components on the manufacturer's website.

When do your brake pads need to be replaced?

It is difficult to make a blanket statement on this. Of course, you will wear out these components much faster if you frequently drive stop and go in the city or generally drive with little foresight. The same applies if you brake very often very late and therefore intensively. Even if you don't use the engine brake, your braking system will be put under more intense strain. On the other hand, the idle time of your car, which leads to the formation of rust, tends to affect the brake discs and brake drums and can usually only do little damage to the best brake pads. However, if your vehicle has been parked for a long period of time, especially in winter or when the humidity is high, you should drive more passively at first and brake harder several times under safe conditions. This helps to remove the rust and, in conjunction with your anti-lock braking system (ABS), also increases safety in traffic – after all, your brakes have to work optimally when it matters! Your vehicle manufacturer specifies a minimum value for the brake pad thickness. The value refers to the actual brake pad and not to the metal element to which it is attached. Four millimeters is usually the lower limit for disc brakes, whereas brake pad thicknesses of at least one millimeter are accepted for drum brakes. These components have either an electronic or at least an acoustic warning signal. A warning light on the dashboard or a characteristic squeak will tell you that your brake pads have reached their wear limit.

Top 8: Ridex

Above all, this brand of brake discs is very cheap. Everyone who pays particular attention to the price will get their money's worth here. However, you should not forget that these are particularly safety-relevant components and the use of branded goods is advisable.

Top 7: Febi Bilstein

The quality of Febi Bilstein brake pads is really high. These are not cheap parts, which can only score with their low price. With these components you can be sure of the desired brake function.

Top 6: TRW

This brand not only convinces with good brake pads, but also with an excellent price-performance ratio. The range is diverse, so you will certainly find the right spare parts for your car.

Top 5: Textar

Textar advertises that it not only reduces the annoying squeaking when braking in various traffic situations, but also with a high level of environmental friendliness. According to their own statements, they contain hardly any environmentally harmful substances. Thanks to almost a hundred years of experience, the company is now one of the leading manufacturers in the brake sector.

Top 4: Bosch

Bosch is one of the top companies in the field of spare parts suppliers. A small disadvantage of these brake pads, which are among the best, is their increased abrasion. Nevertheless, we can give you an unreserved purchase recommendation for these components.

Top 3: Brembo

The main area of use for Brembo brake pads is racing. Nevertheless, their components are also often used for sports cars because they offer high performance.

Top 2: Strong

These are good components for the average driver who does a lot of city driving. In contrast, the brake pads of our test winner from ATE are particularly stable and powerful even at temperatures of up to 600°C.

Top 1: ATE

This manufacturer of brake pads is our favorite. Here you can clearly see what the best components are and how they should be made. ATE components not only offer a particularly high level of security, they also impress with the required quality and their long service life. In addition, with these components you do not have to worry that these brake pads will squeak. As already mentioned, they are also particularly heat-resistant, which also reduces the risk of the brake discs overheating.

Conclusion

There are many manufacturers of good brake pads. When buying, you must make sure that the material also fits the disc or drum material. If this is not the case, you not only risk accelerated wear of the components, you also run a considerable safety risk.

A tip from CarTipsandmore: Please note this when ordering new spare parts not only on material and dimensions. So it is extremely important that the type of wear indicator fits your vehicle. For example, if your vehicle manufacturer uses an electronic display for the wear limit of the brake pads, they must have a corresponding sensor and a suitable connection cable. On the other hand, if your car does not have an electronic warning system, you will need components with an audible warning. In principle, however, checking the entire brake system is not only part of the work of the TÜV, but also part of the regular checks during an inspection in your specialist workshop.