The crankshaft is a particularly important component in your combustion engine. Even if this is very robust nowadays, crankshaft damage can still occur. The crux of the matter is their high load, because this ensures that the impact movements of the engine pistons are converted into the desired rotational movement for your vehicle drive. Extremely high forces are at work here and this component has a complex structure. So you can easily imagine that a defect in this component usually causes very high repair costs. So that it doesn't get that far in the first place, in the following article we will explain the function of the crankshaft and how you can ensure that it works error-free for as long as possible. However, should problems arise, it is important to intervene as early as possible so that no greater damage occurs. In order to make this possible for you, we will also explain the possible symptoms which can indicate a failure or problems with this component.

Function and structure of the crankshaft

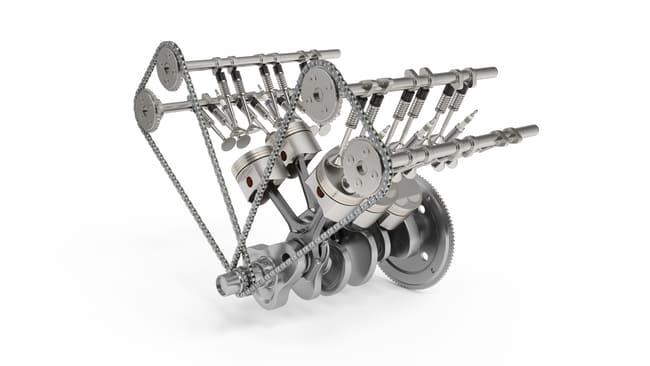

Before we can look at the possible defects and symptoms of the same, you should first understand how this component is structured and how this structure is related to the exact functioning. As already mentioned, the crankshaft in a car is used to generate a rotary movement or torque from the up and down movements of the pistons. This takes place in cooperation with the corresponding connecting rods, which at the same time represent the connection between the pistons and the crankshaft. Another important component is the flywheel. The high load on the components mentioned arises in particular from the constant and very abrupt changes in the direction of movement. This not only creates torsional vibrations, but also the shaft and the corresponding bearings are exposed to torsional and bending forces.

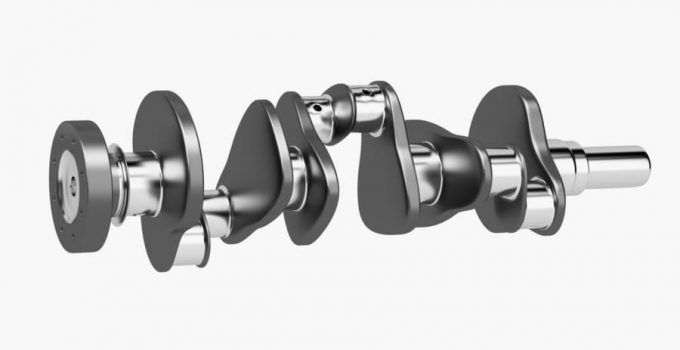

Due to the way they work, crankshafts are made from a particularly tough inner core and materials with very hard surfaces. This is also the reason why most crankshafts are still forged. The raw material used is a so-called nitriding steel or a specially alloyed tempered steel. In addition, parts that are not particularly stressed, such as the bearing journals, are also provided with a surface hardening. The basic components of a crankshaft in a car are crankpins, crank webs, shaft journals and corresponding counterweights. The associated main bearings hold the shaft journals, so that the axis of the rotary movement is also determined by them. On the other hand, the crank pins serve to establish the connection with the connecting rods. The crank webs in turn create the connection between the two types of journals mentioned. To ensure that the rotary movement is as smooth as possible and that no imbalances occur, the counterweights mentioned are also attached to the crank webs. However, the exact crankshaft design depends on the exact engine type. The number of cylinders, stroke height, engine type and engine firing order determine the exact structure. The movement of the crankshaft is monitored by the crankshaft sensor.

The crankshaft wheel, also known as the crankshaft gear, is a component that is responsible for the torque distribution in the vehicle. For example, it drives the oil pump and the intake and exhaust valves of your engine. This component is not one of the engine components that always have to be replaced after a certain period of time. But on the contrary; the crankshaft sprocket is only replaced in the event of problems or a defect.

Symptoms of a defective crankshaft in a car

If your crankshaft is defective, you will recognize this from various symptoms. Several symptoms can, but do not have to, appear at the same time. Some of these can also be understood as early warning signs, while others only appear when the crankshaft has been seriously damaged. Some of these are also not necessarily specific to crankshaft bearing damage or similar defects, but can also occur with other problems. In this case, we recommend that you use the process of elimination and gradually rule out all possible sources of error. In principle, an incorrect, i.e. too large or too small, axial play of the crankshaft plays an important role in problems with this engine component.

In modern engines, thankfully, serious damage to the crankshaft is rare. One of the reasons for this is that these components can now withstand even more extreme loads. Nevertheless, such engine damage can still occur if there is a lack of engine oil or if the engine speed is much too high. Whereby a speed that is significantly too high is actually reliably prevented by the engine electronics. Nevertheless, a mistake when changing gears in connection with a sporty foot on the accelerator can definitely cause a fracture of the crankshaft. Imagine that you are driving at high revs in third gear and now you want to shift into fourth gear; Now you get the second gear instead – with a bit of bad luck you have caused a very serious engine damage.

However, we come to the second, much more common cause: the lack of engine oil. Sooner or later, this will not only lead to crankshaft bearing damage, but also to the connecting rod bearings being affected. If there is no more oil, the dry friction usually takes its full toll after 10-15 minutes at the latest. Since a turbocharger, which is often present in modern vehicles, is usually much more sensitive (after 10 minutes without oil, a lot is already over), the crankshaft is usually not so badly affected. You can usually recognize crankshaft damage based on the typical noise development. If you hear a click, which adapts to the engine speed, this usually indicates defects in the connecting rod bearings. If you can hear a rumble or rumble deep inside your engine, the crankshaft bearings are affected. In any case, do not continue driving and turn off your engine immediately if you experience these types of symptoms to avoid even more serious damage.

Conclusion

The crankshaft is one of the most stressed engine components. In particular, the bearing shells of the crankshaft can easily wear out. Nevertheless, this engine component is low-maintenance and only needs to be replaced or repaired if a problem occurs. In most cases, however, the engine then has to be dismantled, so that the repair costs quickly increase. It is best to get comprehensive advice from your specialist workshop on how economical an engine repair is in this case.

A tip from CarTipsandmore: Even today there are still specialists or special companies who do carry out grinding of crankshafts. This is a special form of repair, which can partially restore the smooth running of the engine. However, in order for such a process to be successful at all, extremely precise measurement and processing of this sensitive engine component is necessary. This type of repair can also only be used for minor component damage, so you should always pay attention to the symptoms mentioned above so that it is not too late in the end and much greater damage occurs.