Combustion engines are still among the most common engines and are in found in many vehicles, both motorcycles and cars. But that doesn't mean that everyone knows how a car works and what processes are necessary to drive it. Perhaps you have already asked yourself: “What is a petrol engine?” Or more generally: “How does an engine work?” Don't worry, in this article we will explain it in such a way that you don't have to be a car mechanic to keep track of things .

In short, an internal combustion engine converts the thermal energy generated during combustion into mechanical work, which then propels the car. This article will cover the 4-stroke engine, which has been in use for over 100 years. First of all, it is important to know that a petrol engine works differently from a diesel engine. Not only is the fuel used different – petrol in the first and diesel in the second – but also the type of ignition. The gasoline engine is a spark igniter with a spark plug that produces an electrical spark that ignites the air-fuel mixture. The diesel engine, on the other hand, is a compression-ignition engine. In detail, this means that an external spark is no longer required for ignition in the combustion chamber, since the air is heated to approx. 600-900 °C and ignites all by itself with the then injected fuel and the subsequent compression.

These two different internal combustion engines each owe their names to their inventors. The Otto engine goes back to the German inventor Nikolaus August Otto. Although he did not generally invent this type of engine, he did develop the 2-stroke engine into a 4-stroke engine in 1876. The engineer Rudolf Diesel invented the diesel engine not too much later, namely in 1893.

Contents

An engine must be able to breath

You can imagine the processes in a combustion engine a bit like breathing: the intake valves open, fresh air and fuel flow in and are then expelled via the exhaust valves when they have been burned and thus used up.

Now let's take a closer look. Everything starts with the driver. He steps on the gas pedal and opens the throttle valve. Depending on how hard the pedal is pressed, the degree of opening of the flap also changes, which also determines how much air is directed through the intake manifold to the engine. The injector adds the right amount of fuel. Depending on how much of the air-fuel mixture gets into the cylinder, the combustion is stronger or the piston weaker, so you “gas” more or less.

Construction & Components of the 4-stroke

All this is still understandable when you sit behind the wheel and control the speed of the vehicle yourself, but this does not yet explain the engine design. What exactly happens inside the cylinder engine, what are its components and how does it generate the power that drives the car?

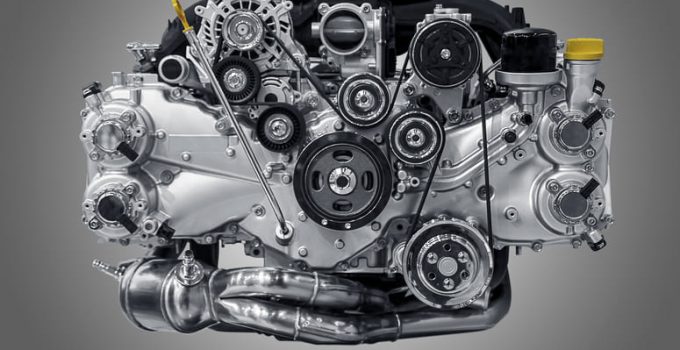

The engine consists of several cylinders. A piston moves up and down in a cylinder. The highest and lowest point that the engine piston reaches is called the top and bottom dead center, the volume in between is the so-called cubic capacity. This term usually also refers to the engine size. Of course, you have to add up the displacements of all existing cylinders. The larger the displacement, the more powerful the car.

Via a connecting element – the connecting rod – the upward and downward movements of the piston are converted into a rotary movement of the crankshaft, which is located centrally below the cylinder, which in turn transmits this movement to the gearbox and thus drives the wheels. The crankshaft is also part of the processes summarized under the term mechanical engine control:

It is connected to the camshafts – there are one or two – via the timing gears and either a toothed belt or a timing chain and drives them. They run above the cylinder heads and control the intake and exhaust valves. Therefore, the exact match between all these elements is imperative so that the valves and the piston in the cylinder do not collide and a clean gas exchange is possible. The valves are located on the cylinder head, and their number can vary. In between is the spark plug, which triggers an explosion and thus combustion. This keeps the piston moving and the engine running.

The 4 strokes of a combustion engine

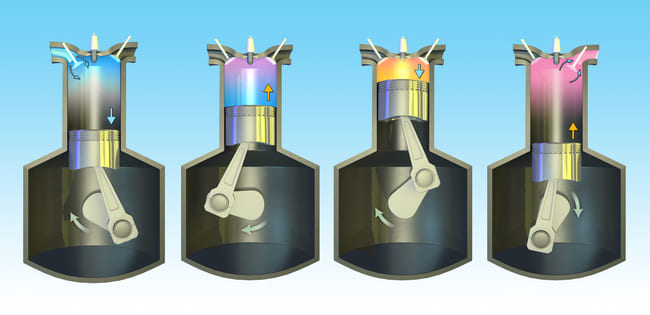

As the name of the 4-stroke engine already suggests, the process in engines is divided into 4 strokes:

- Intake stroke

- Otto: The position of the piston is top dead center. The intake valves open and the downward movement of the piston draws fresh air/fuel mixture into the cylinder. The inlet valve closes when the piston has reached the bottom.

- Diesel: In the first stroke, only air is sucked in through the open intake valves.

- Compression stroke

- Otto: During the next step all valves remain closed. The piston moves back up and thus reduces the space in the cylinder, which means that the mixture is compressed, i.e. compressed. The efficiency increases with the compression ratio, however, higher compression carries the risk of unwanted self-ignition of the mixture.

Due to the compression, the gas mixture in a petrol engine reaches a temperature of approx. 450 °C. - Diesel: The valves are closed and the air drawn in is strongly compressed by the piston moving upwards. It is heated so much that it reaches a temperature of approx. 650 °C or more.

- Otto: During the next step all valves remain closed. The piston moves back up and thus reduces the space in the cylinder, which means that the mixture is compressed, i.e. compressed. The efficiency increases with the compression ratio, however, higher compression carries the risk of unwanted self-ignition of the mixture.

- Working cycle

- Otto: As mentioned at the beginning, only the design of the Otto engine includes a spark plug. This is used in this cycle: just before the piston reaches its top dead center, it adds an electrical spark that causes the air-fuel mixture to explode and burn. The pressure causes the piston to move back down.

- Diesel: With this type of combustion engine, the diesel fuel is only injected into the cylinder in this cycle, where it meets the highly heated, compressed air and self-ignites directly due to the high temperature and thus causes the desired explosion. The piston is pushed down.

- Exhaust stroke

- Otto: In the last step, the exhaust valve is opened so that the exhaust gases, caused by the combustion of the fuel can be removed from the cylinder. After being filtered, they are expelled from the vehicle through the exhaust pipe.

- Diesel: This cycle is the same, here too the combustion gases are directed outside through the exhaust valve.