A gasoline engine relies on the injected fuel to be ignited in the combustion chamber. This is done with the help of the built-in spark plugs, with the overall ignition system in the car also providing the necessary high voltage and ensuring the right timing. It is essential for a smoothly running vehicle engine that the fuel-air mixture in the individual cylinders is actually controlled and ignited at the desired point in time. If the timing is not right, a characteristic knocking occurs or you even notice real misfiring. Both quickly damage your engine and you can very easily suffer from serious consequential defects if you ignore problems with the functioning of your ignition system. In the following article we explain what is meant by an electronic ignition system and explain the structure and types of ignition systems. We will then provide you with information that you can use to diagnose an ignition system defect yourself in no time at all.

Contents

The structure of an ignition system

Basically everything that is needed to generate a high-voltage ignition spark in the area of the engine spark plugs belongs to this system. For this purpose, for example, the existing low on-board voltage must be converted into a suitable high voltage. But first things first: A car ignition system that was common in the past included one or more ignition coils, an ignition distributor, ignition contacts, capacitors, the centrifugal vacuum adjustment device and a sufficient number of ignition cables and spark plugs.

The ignition coil generates the actual high voltage. The primary winding is particularly thick and the secondary winding is rather thin and filigree. Both windings run over a magnetic core. This structure allows the on-board voltage to be transformed from mostly 12 volts to an ignition voltage in the range of a few thousand volts. The ignition distributor has the task of always making this high voltage available to the corresponding spark plugs at the right time. In the ignition distributor you can also adjust the capacitor, the breaker contacts and the settings for vacuum and centrifugal force in order to correctly adjust the desired ignition timing. The ignition cables to the ignition coils and to the individual spark plugs are connected to the ignition distributor.

The ignition cables used are special high-voltage cables, which transmit the ignition voltage based on the actual requirement. Today, this type of cable is often screwed to the engine block. The ignition contacts in the ignition distributor are responsible for the primary circuit being closed or opened as required. The timing is mainly done by the distributor shaft cams. Because the build-up and break-down of the primary circuit involves the risk of sparks due to the voltages, a dedicated capacitor is used to intercept them.

The vacuum centrifugal adjustment device allows the ignition system in the car to be adjusted. This is used to set the ignition point so that it always matches the engine load and the corresponding engine speed. In general, the maximum gas pressure generated by the combustion is controlled in such a way that the best possible efficiency is achieved. Therefore, the air-fuel mixture is ignited shortly before the end of the second stroke (the compression phase), because the combustion takes about 1/3000 second. This time is independent of the current engine speed, so the ignition system must be controlled and adjusted when the engine load changes.

Transistor ignition systems and all-electric ignition systems

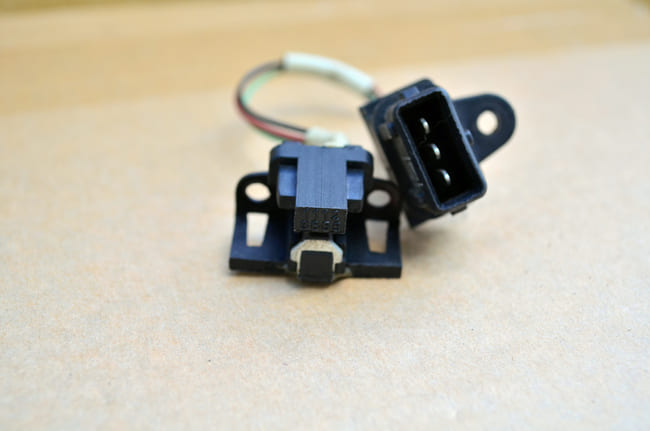

Nowadays, mechanical ignition systems are rarely used, especially because the adjustment of the parameters of the ignition system can be complex and error-prone. For this reason, so-called transistor ignition systems are often used today, or all-electric ignition systems are used straight away. In a transistor ignition system, the ignition contacts are replaced by transistors, which reduces their wear. A Hall sensor in the ignition distributor determines the information about the correct ignition point.

Real electronic ignition systems no longer have any moving components. Hence their alternative designation „dormant ignition system“. The actual control is handled by the multifunctional engine control unit. Sensors for engine speed, engine temperature, engine load and knock sensors are used. A so-called three-dimensional map not only ensures optimal performance, but also reduces fuel consumption.

Ignition system problems

When you start the engine, your ignition system is powered by the car battery. If this is not sufficiently charged, no ignition spark can of course be generated. This will prevent you from starting your vehicle even though the starter may be working properly.

However, now that you know the basic structure of an ignition system, you can more easily understand the effects of a failure of a specific component. A problem may arise, for example, when the ignition coil(s) fail. Examples of this are age-related winding short circuits, mechanical damage or contact problems. An ignition coil defect can manifest itself through various symptoms.

Misfires, uneven engine operation (e.g. jerking), an increase in consumption, your engine warning light coming on or the engine no longer starting often occur. As soon as you have the suspicion that your ignition coil could have a problem, you should no longer load your vehicle engine, but simply switch it off. This is the only way to avoid possible consequential damage.

The ignition cables are also among the components of the ignition system that are more likely to have a defect. It can also happen that these loosen. If you have problems with the ignition and the engine starting, you should first reconnect the ignition cables after checking the battery charge level. You should also take a close look at the condition of the cables. This is the only way you can recognize possible signs of marten bites or even worn insulation. In both cases, you have no choice but to replace the ignition cables. Good insulating tape may also be sufficient for a short-term remedy.

Misfires and starting difficulties in your engine can be traced back to worn spark plugs. Dismantle these for a condition check. They should not be dirty or mechanically damaged.

Furthermore, the spark plugs must also be replaced regularly during engine maintenance.

Conclusion

In the meantime, ignition systems in cars require significantly less maintenance because there are no longer any moving parts, and allow for significantly greater flexibility. Tuning fans also like to use the possibilities of electronic ignition systems because they can provide significantly more engine performance through so-called chip tuning. The stored 3D map is manipulated according to your own requirements. But even the most modern ignition system fails when the car battery is empty.

A tip from CarTipsandmore: The spark plugs are also an important part of your car's ignition system. You should therefore also observe their maintenance intervals. You need the right spark plug wrench to remove and install them. Special tools are sometimes required for this, because some manufacturers use special hexagon or even twelve-point sizes. Find out in advance which tools you need exactly so that you don't have to experience any nasty surprises.